Whenever I mention having a garden paradise, my Jeremy reminds me that a garden won’t benefit us in the long run like a remodeled basement. And he is right.

Finishing your basement is the easiest way to increase your home’s square footage, add storage, and add to your resale value. The simple task of insulating your home can save you up to 35% of your energy costs. And that in itself is reason enough for me and my boyfriend to jump feet first into starting. I thought I might share the process with you so that if you can save some cash too!

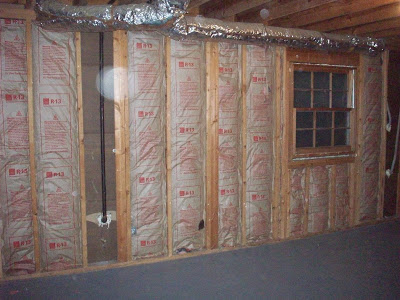

Welcome to our basement!

The plans were for this area to be a bedroom. We both agreed we wanted to remodel this space only one time…so we needed to brainstorm before we began. And we needed to do a little research on the subject of waterproofing and insulating.

Here are some of the resources that we found:

STEP 1: RESEARCH FOR YOUR SPACE

If you decide to tackle this project yourself – do your research first. It will save you time and money in the long run. Also, every basement is different so don’t be afraid to ask questions. Some of the best recommendations are found from professionals on those message boards online. And don’t be afraid of sounding stupid – I think those guys are used to dealing with idiots.

STEP 2: PREP YOUR AREA

We have had no evidence of water seepage, humidity or mold so we were able to skip ahead to sealing and prep work. The first areas to tackle were the floor and exterior walls.

Clear and clean the area to be sure that it is free from clutter, dirt, dust and any stray cobwebs.

Clear and clean the area to be sure that it is free from clutter, dirt, dust and any stray cobwebs.

STEP 3: BUY YOUR SUPPLIES

This is the product we used on our floor. WARNING: we did get high…this is powerful stuff people and I recommend opening every door and window possible, use a fan, and then if possible get out of the house. It was so strong that I could smell it four days later when I opened the garage door…just be aware!!!

This is the product we used on our floor. WARNING: we did get high…this is powerful stuff people and I recommend opening every door and window possible, use a fan, and then if possible get out of the house. It was so strong that I could smell it four days later when I opened the garage door…just be aware!!! And this is what we used on our cinder block wall. Note that the recommended layer is very thick so it is not the time to be frugal 🙂

And this is what we used on our cinder block wall. Note that the recommended layer is very thick so it is not the time to be frugal 🙂

Great Stuff is great stuff! This foam fills all sorts of crevices, holes and areas that bugs come in and heat goes out.

Ah – the blessed insulation. Me and the pink panther – yea we are buddies – he is gonna save me some moolah 🙂

Ah – the blessed insulation. Me and the pink panther – yea we are buddies – he is gonna save me some moolah 🙂

STEP 4: APPLY YOUR WATER SEALANTS

We applied the floor sealant much like you would paint. Make sure you don’t use your favorite paint roller pan cause this is oil based and will need to be properly disposed of so that you don’t have the strong vapors living in your lungs. YUCK!

The block wall had the sealant applied with a paint brush. Again – oil based so use a brush you don’t love.

STEP 5: STUD OUT YOUR SPACE

Jeremy is usually all the stud I need 🙂

Your first stud is gonna be attached directly to the concrete floor. They have these great stud guns at Home Depot – it is great cause you can attach wood to masonry (and your boy feels like because it has gunpowder shells, it is a real gun!) Either way – it doesn’t take a lot of shots, just make sure it is nice and tight to the floor.

See the little orange dot? That is the “nail” that attached the stud to the concrete.

Then go about attaching studs to both sides and across the top – the studs in between should be 16″ apart from center to center.

STEP 6: FILL THE GAPS

Remember the ultra clever title of stuff that fills cracks and gaps? Yea – take that Great Stuff and squirt till your hole is full. The foam hardens up pretty quick but I like to give it at least a full 24 hours till I mess with it. Sometimes I miss something in that time period – so the waiting period gives me an extra chance at thoroughness. Apparently we had a lot of stuff to fill! Wow – the picture just shows every chance our precious warm air got out…didn’t it?! Don’t forget about going around those windows!

STEP 7: INSULATION BETWEEN STUDS

Fiberglass insulation is really REALLY bad for you if you inhale, swallow, or let it contact your skin. Just touching it can make embed those fibers in your skin – and boy! you will itch for a long time so be prepared. A pair of googles, a mask, gloves and covering your arms and legs would be a good idea.

Insulation can be cut with a pair of kitchen scissors and needs to be stapled to the inside of the studs on exterior walls. They make the insulation with a paper backing (that goes in the front) with a cute flap that is perfect for stapling. Staple it every 10-12 inches on both

sides. Make sure you attach it far enough back that any electrical wiring can be inserted.

Insulation can be cut to fit around pipes because you will want the pipe in the front. We got all of this done in one week and for a meager budget:

For a 16ft by 16ft room it cost us about $200. But in the long run it’ll save us WAY more than that…it better anyway 🙂

We have more to come – we want to take this project ALL THE WAY BABY!

I love it when we can share and I love it even more when others share with me – if you have a tip to share from your latest basement remodel, please leave it in the comments section so that others can benefit from your mistakes (err, I mean wisdom!)